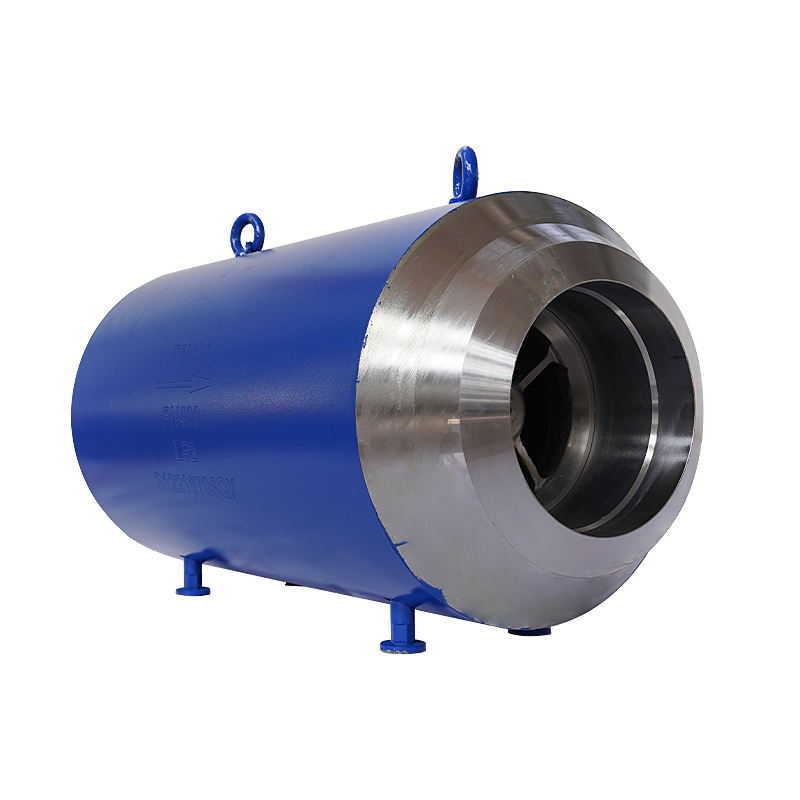

Nozzle (Axial) Onani Vavu

| Kuponya | |

| Chitsulo cha Carbon | WCB, WCC |

| Low Kutentha Chitsulo | LCB, LCC |

| Chitsulo chosapanga dzimbiri | CF8, CF8M, CF3, CF3M, CF8C, CF10, CN7M, CG8M, CG3M etc. |

| Aloyi Chitsulo | WC6, WC9, C5, C12, C12A |

| Chitsulo cha Duplex | A890(995)/4A/5A/6A |

| Nickel-Based Alloy | Monel, Inconel625/825, Hastelloy A/B/C etc. |

| Kupanga | |

| Chitsulo cha Carbon | A105 |

| Low Kutentha Chitsulo | LF2 |

| Chitsulo chosapanga dzimbiri | F304, F316, F321, F347 |

| Aloyi Chitsulo | F11, F22, F5, F9, F91 |

| Chitsulo cha Duplex | F51, F53, F44 |

| Nickel-Based Alloy | Monel, Inconel625/825, Hastelloy A/B/C |

Nantong TH-valve imadziwika kuti imapanga ma valavu apamwamba kwambiri a "non-slam" omwe amapereka chitetezo chodalirika ku ma surges ndi kubwerera m'mbuyo pamagwiritsidwe osiyanasiyana amadzimadzi, kuphatikiza ma axial flow.

Chimodzi mwazopereka zathu zazikulu ndi banja la ma valve owunika ma nozzle, omwe amagwira ntchito ngati yankho labwino kwambiri popewa kubweza m'mbuyo pafupifupi ntchito iliyonse.Zopangidwa makamaka kuti zizikhala zotsika kapena zoyenda pang'onopang'ono, ma valve awa amatsimikizira kutsekedwa mwachangu komanso mwakachetechete pa nthawi yocheperako kapena yosayenda.

Ma valve owunika a Nozzle amagwiritsa ntchito diski ngati njira yotsekera, yomwe imagwiridwa ndi mpando ndi kasupe wamkati.Pamene kuthamanga kwa madzi, gasi, kapena slurry pa malo olowera kumadutsa mphamvu yotseka ya kasupe, valavu imatsegula, ndikulola kuyenda bwino.Kuthamanga kukachedwetsa kapena kuyimitsa, kasupeyo amangotseka valve.

Mapangidwe apadera a ma valve owunika a nozzle amapereka zabwino zingapo:

1.Kuyankha komanso kuchitapo kanthu potengera kusintha kwa kuthamanga kwa kuthamanga ndi kuthamanga.

2. Kuchepetsa kuchepa kwa kuthamanga.

3.Kupewa kapena kuchepetsa nyundo yamadzi ndi zotsatira zake zowononga.

4. Kuchotsa macheza a valve panthawi yotsika kwambiri.

5. Kutetezedwa kwa mapampu ndi zida zozungulira kumayendedwe obwerera.

6. Kuchita kwa zero kutayikira poyerekeza ndi mitundu ina ya ma valve cheke.

Makamaka, ma valve owunika ma nozzle awonetsa magwiridwe antchito apamwamba pamafakitale opangira mankhwala ndi mafuta.Ma valve awa amalepheretsa kubwereranso kumbuyo pamene akupereka mphamvu zodalirika zotseka.Muzochita zomwe zimafuna kulinganiza koyenera kwa zigawo, monga ethanol-additive blending, chitetezo ku kubwerera mmbuyo ndichofunika kwambiri.

Sankhani ma valve owunika a Nantong TH-valve kuti agwire bwino ntchito, kudalirika, komanso kukwanira m'mafakitale ndi ntchito zosiyanasiyana.